Regardless of your industry, the transition away from traditional internal combustion engine (ICE) vehicles to a range of electrified vehicles, including battery electric vehicles (BEVs), hybrid electric vehicles (HEVs) and plug-in hybrid electric vehicles (PHEVs), is charging ahead. In fact, fleet managers already have a wide array of options on the market, from hybrid to full-electric vans and trucks. And many more innovative models are currently in development and production, slated for launch in the coming months and years.

With the current administration pushing to ensure half of new U.S. fleet vehicles are electric by 2030—as well as ambitious public and private plans to increase electric vehicle (EV) charging stations—it’s apparent that now is the time to start planning your fleet electrification strategy, or risk getting left behind. And with a lead time of up to two years for large fleets to fully electrify, it’s never too early to get started.

Going electric puts you in good (global) company.

Nearly two-thirds (up from one-fifth in 2020), of the world’s 2,000 largest public companies have committed to “net zero,” meaning they’ve agreed not to add new emissions to the atmosphere. Meanwhile, the UN has asked the world to aim for net zero by 2050. If you aren’t already, now is the time to think about reducing your carbon footprint through electrification—a move that is good for the planet and a boost for your brand, considering two-thirds of North Americans prefer “eco-friendly” brands.

Additionally, switching to electrified vehicles can add up to significant savings for total cost of ownership (TCO). Electric power is reliably less expensive than gas, with cost savings making up for the higher acquisition costs within the first two years of ownership. Fully electric vehicles also have much lower maintenance costs—with $0 for oil changes and less wear and tear on brakes.

Finally, the current average cost of EVs versus ICE vehicles is much more comparable today than ever before. In 2023, the average cost of an ICE vehicle is $45,578, up from $40,000 in 2020. In comparison, there are a dozen EVs available for under $50,000.

With so many benefits, going electric is definitely the future of fleet management. But it isn’t something you can snap your fingers today to make happen tomorrow. Electrifying your fleet is a complex, long-term process that requires careful planning and preparation.

The road to charging starts with the right mindset.

From overcoming range anxiety to satisfying installation needs, the first step toward a successful transition to an electrified fleet is actually a shift in mindset. Jason Kraus, Director of Vehicle Acquisition & Lease Structure at Mike Albert, challenges fleet owners not to think of charging vehicles as time spent waiting. Rather, it’s a passive process that happens when you’re not using the car.

“Think of charging your EV like plugging in your cell phone. You don’t wait for it to charge, you just charge it while you’re sleeping or not using it,” said Mary Perry, Manager of Partner Products at Mike Albert. “The time it takes to fuel with fossil fuels is active time you sit at the pump and monitor the liquid. But EV charging is passive. There’s no need to stop by a gas station with EVs.”

Charging up: choosing a level

In most cases, it’s far less expensive to charge a BEV than it is to fuel up an ICE vehicle with gasoline...when done correctly. To ensure the lowest cost, you’ll want to charge at home or depot chargers, as opposed to relying on the public network.

However, different facility chargers come with different benefits.

- Alternating Current (AC) or Level 1 charging (110v) - Refers to charging used with an ordinary household outlet that can take about a day to charge.

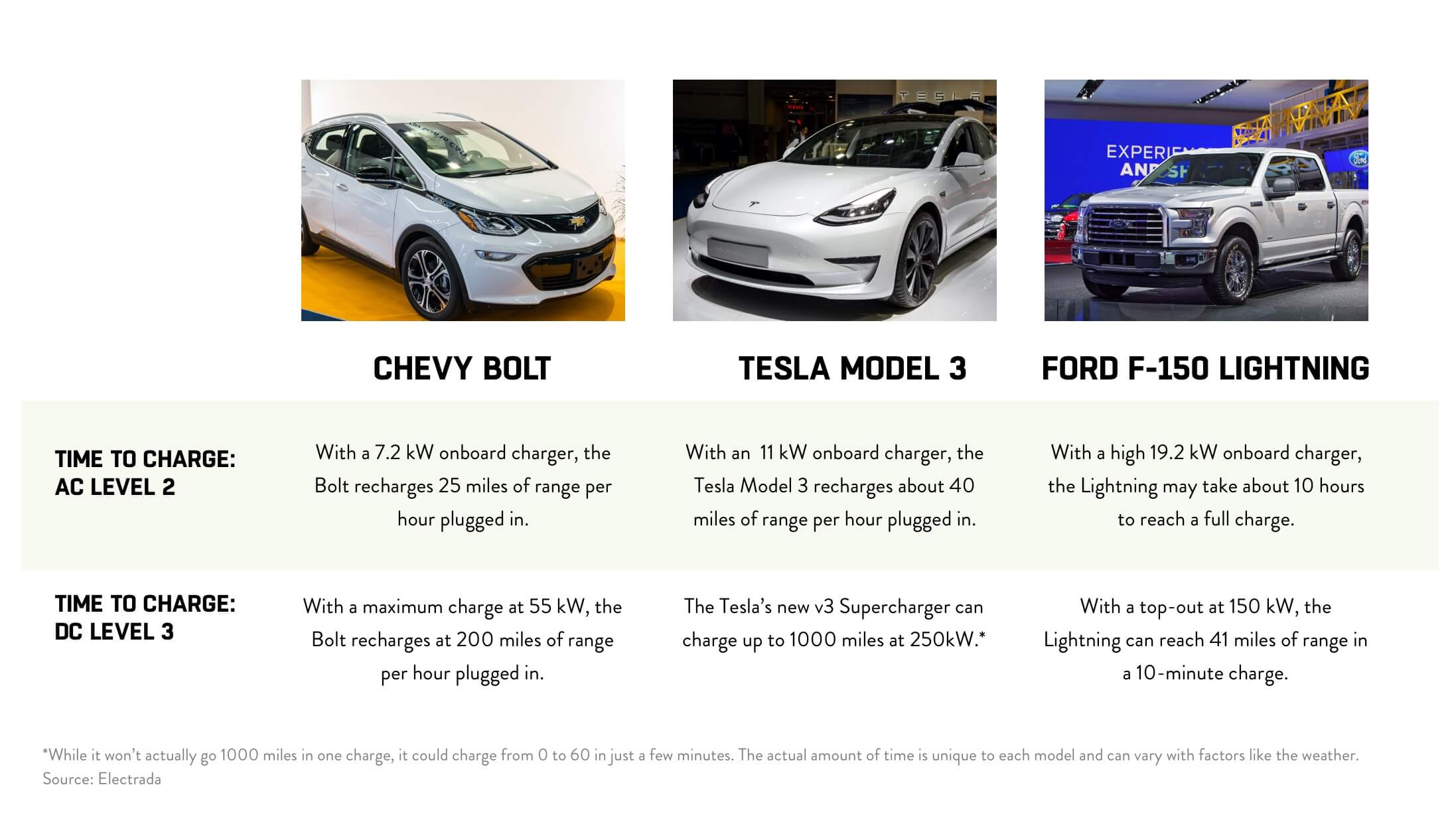

- Level 2 charging (208-240v) - Uses a similar amount of power as an electric dryer. Typically hardwired as opposed to an electric outlet. Depending on the charging station and vehicle, Level 2 usually adds 20-40 miles of range per hour plugged in.

- Direct current (DC) Fast charging - Off-vehicle charging unit that hooks up the battery directly through the car's charge port. DC charging is much more powerful than a vehicle’s onboard charger and can charge much more quickly. Large vehicles like buses and semi trucks only charge via DC charging.

If you are installing Level 2 charging, it may make sense to have one charger per vehicle, as charging typically takes place off-shift. If you opt to install DC chargers, which increase installation costs per unit, your vehicles can charge in about a tenth of the time of an AC charger—so you’d ultimately need fewer chargers to power your fleet. Some fleets will primarily install AC chargers for passive off-shift charging, with a few DC chargers as a back-up in case of unplanned detours that leave your vehicles short on range.

Keep in mind the impact of temperature on the range achievable with the battery. The optimum temperature for lithium-ion batteries hovers around 70 degrees Fahrenheit, losing approximately 20% as temperatures get above 100 degrees Fahrenheit or below 32 degrees Fahrenheit; it’s important to note that range is not impacted by the heat index (temperature + humidity) or wind chill (temperature + wind). Lastly, when charging at home or depot, drivers should utilize preconditioning to optimize the vehicle’s range using electricity from your home or business to adjust the battery (as well as the cabin) to the optimum range. Your drivers will love having the right temperature in the cab, while you’ll enjoy the benefit of maximizing the range for your operations.

Note that there isn’t any “one-size-fits-all" answer for how quickly it takes to charge a vehicle based on the level of charging. Different makes and models come with different charging speeds, which vary from model to model.

Charging up: time-of-day impact

Unlike gasoline prices, which fluctuate due to seasonal changes or crude oil supply disruptions, electric charging prices can vary depending on the time of day. For example, you may pay less at night and more during the day. This practice recently started being used in California by EVgo, and occasionally Tesla’s Superchargers will institute surge pricing based on demand, said Funnell.

“Imagine if you put gas in your car at midnight and it was $2 a gallon, but at noon, it was $4.50 a gallon. That’s similar to how peak times with electric charging works,” Nate Shadoin, director of fleet electrification at Mike Albert, said. “Some charging software only allows vehicles to charge at a certain rate, and they might slow it down during the day or increase the speed at night.”

Owners of electric fleets have to consider these peak rates and ensure they are charging vehicles at the right time so as to not overpay for power. Working with a specialized electric fleet partner can help because they can negotiate with utilities, and make sure fleet owners won’t have to worry about peak charging times.

The fleet electrification process

If you think electrification might be right for your fleet in the coming years, it’s smart to start planning now. Much like creating an optimal route for your drivers, you can set up a plan for success, hitting all the key mile markers along the way, right on schedule.

Consider all your electrified options.

Even if your ultimate goal is total electrification, there are many ways to incrementally drive toward a more electrified, sustainable fleet. “I jokingly say that you're going to have to stop in Hybridville before you get to EV Town,” said Kraus. That more practical approach can mean embracing all the electrified options, including HEVs and PHEVs. With generally lower purchase costs and comparable energy costs when combining fuel and electricity spends, the hybrid option can make good sense from a financial perspective. This is especially true for smaller vehicles, like sedans and cross-over SUVs. When it comes to trucks, however, it’s a better deal to go straight to full EV as the gasoline costs are so much greater for larger vehicles.

Seven steps to successful fleet electrification.

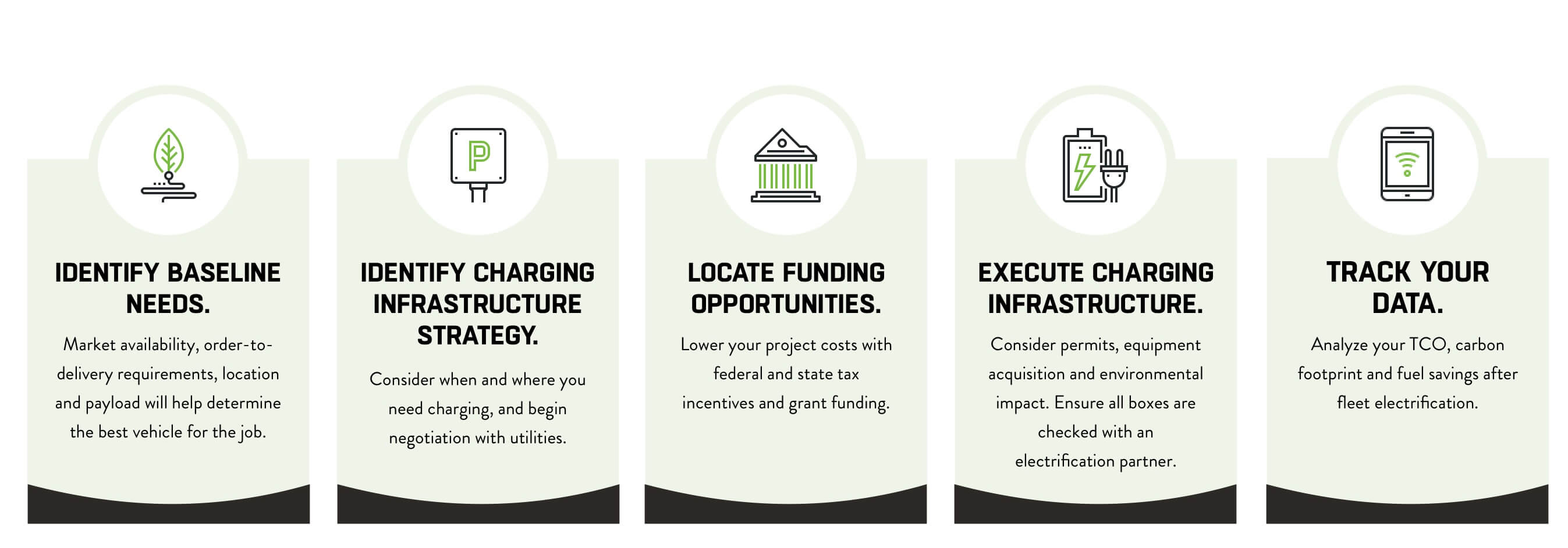

1. Engage the right partner. A good FMC will analyze your current fleet and conduct an Electric Vehicle Sustainability Assessment to identify if certain drivers, routes, or vehicles are the best fit for transitioning to EVs.

2. Identify your baseline needs. Do you operate primarily in an urban environment, or do your vehicles typically travel 300+ miles daily over interstates? Does your industry require you to haul heavy loads, or can you opt for smaller vehicles? What is the status of your current fleet — is it almost time to cycle out for new vehicles, or can your current vehicles still last you a few years? What’s your daily average speed?

How you answer these questions will determine if your fleet is best suited for an electric truck, van, sedan or going the hybrid route.

3. Conduct a cost-benefit analysis. On average, a new electric van or truck costs about $4,500 more up front than an ICE vehicle. However, an average spend of $3,000 on gasoline each year would be replaced with a charging spend of about $500, saving you $2,500. In less than two years, your initial up-front cost could be covered. That’s not even factoring in savings on oil changes and other maintenance costs, estimated at up to a 40 percent savings. For you as a fleet manager, calculating how long it will take to make up that initial up-front cost is a key step in making the switch.

4. Consider time spent idling. Don’t just go with your gut on this one—review your telematics to find out how much time each day your vehicles typically spend idling. Depending on the size, running the engine without covering any miles can quickly add up in fuel costs. Compact cars with 2-liter engines consume about 0.16 gallons per hour. A large sedan with a 4.6-liter engine consumes just over twice as much fuel at idle, or over a quart. That can easily equal thousands of dollars across your fleet per year, and it’s a cost that’s totally eliminated with EVs and hybrids.

5. Research the type of charging equipment you’ll need. Installing charging infrastructure is complicated. Different vehicles require distinct types of chargers, and the different charging levels vary in pricing and charge times. You’ll also need to determine if you’ll go with home or depot charging, filling in with public charging as needed.

6. Locate and apply for grant funding. Tax incentives and grant funding can go a long way to making electrification more affordable. Federal tax credits can give you up to $7,500 back, and states often have additional incentives. Grant funding can also be an option for offsetting costs. If you live in a locality where grant funding is not available or you’ve been waiting for too long, a fleet electrification partner can help you strategize other ways to achieve lower costs.

7. Execute the charging infrastructure. From contracts that vary by city or county, to environmental considerations, to sourcing the actual chargers — the devil is in the details when it comes to installation of charging infrastructure.

8. Track your data. Data is the backbone of effective fleet management. After electrification, you’ll want to start continuously tracking data such as:

- Total cost of ownership compared to ICE vehicles, including down payments, fuel savings and charging infrastructure costs

- Carbon reduction

- New leads and sales after environmental positioning

- Employee satisfaction and retention for those driving EVs, as well as attracting new talent

Typically, once a fleet owner sees this data and compares it to historical data, it solidifies their decision to set more procurement goals for BEVs in the future.

Potential roadblocks en route to electric.

Whether it’s from the government or utilities, expect to spend time and energy navigating roadblocks like bureaucratic red tape and complex permit processes. You will need to work with various parties including utility providers, property managers, environmental consultants and more to ensure you stay compliant on the road to electrification.

“In an emerging market like EVs, working with partners where there is an existing relationship with well-established charging equipment vendors is very useful,” Perry said. “Oftentimes there will be a requirement in an obscure code somewhere that isn’t always obvious, but a fleet partner can help you identify those.”

Property leasing considerations.

Many fleet owners have long-term leases on their facility as opposed to owning them outright. When leasing, you must take into consideration how to improve a property that does not belong to you. This might mean negotiating with the owner to pay for improvements or getting a lower price in rent in exchange for covering up-front costs of charging.

There is always the risk that the property owner may not allow such modifications. Come to the conversation armed with a plan, whether that’s providing data points on the rise in EV to convince the property owner to pay for these improvements or even uninstalling charging tech upon the termination of your lease.

Similarly, if your drivers will be utilizing home chargers, your business may need to arrange to pay for all or part of the setup. Further, if the driver’s home or apartment is rented, an arrangement must be made with the property’s owner or landlord.

Capital costs for ongoing upgrades.

Buying electric chargers, hiring contractors to install them and paying for continuous upgrades are just a few of the many capital costs involved with a fleet electrification strategy. Fortunately, all of these speed bumps can be mitigated with the assistance of an electric-focused fleet partner who can:

- Acquire all necessary permits, research government regulations and incentives and negotiate with utility companies

- Address concerns from property owners or landlords and uninstall electric equipment at the termination of a lease agreement, if necessary

- Handle all the capital costs including acquisition, installation and charging upgrades, allowing for one easily payable invoice

Why opt for a fleet electrification partner?

A well-planned, step-by-step strategy is the best route to electrification success—and the right fleet electrification partner will work closely with you throughout that process to help you achieve optimal results, from identifying your needs and assessing your fleet to establishing your charging infrastructure and tracking results.

That's where Mike Albert can help. Our company has avidly supported the use of EVs in fleets for well over a decade, and today, we are one of the nation’s top leaders in fleet electrification and management. Our EV team has developed strong relationships with manufacturers and acquired extensive EV product knowledge through nonstop research and hands-on experience. We put all this expertise to work for your organization by helping you design a holistic plan for integrating the right EVs and charging solutions into your fleet operations.

“Our motto is ‘We handle everything you need to power EVs,’” said Kraus. “We know the ins and outs of what it takes to get you to the front of the line.”

To learn more about the future of fleets, talk to a fleet electrification expert with Mike Albert today.