It's 9:45 a.m. on Wednesday, and one of your drivers calls, saying his vehicle has been making a loud, squealing noise recently — and now he's on the side of the road awaiting a tow truck. Ugh! He calls again 90 minutes later with news that the technician at your go-to maintenance shop is fully booked, but promises to squeeze in your vehicle; however, as the hours tick by, it's not looked at until 3 p.m.

By 4 p.m., the verdict is in. A damaged alternator. $700 total for the tow truck and repair, not to mention an entire day of deliveries postponed while your driver sat at the shop. The cause — a busted drive belt. What’s worse? You have a full day of appointments tomorrow for your HVAC service, and there’s no way you can get the jobs done without this vehicle. What choice do you have?

In reality, many parts of this situation could have been avoided, starting with the driver alerting you to the squealing noise, so the damaged drive belt could have been fixed for $75 when the oil was changed with other scheduled preventive maintenance — then the alternator wouldn't have needed to be replaced. You may console yourself by thinking of this pricey repair as an “investment” in the vehicle’s future. But the reality is, this fix won’t necessarily guarantee the vehicle will run longer.

When you stay on top of fleet maintenance, your fleet operations run smoothly, your drivers are happier and you can control vehicle maintenance costs. Incorporating a managed maintenance program into your operations is key. The right program ensures your company’s vehicles are taken care of in a timely and appropriate manner. Even better, a program powered by software and telematics not only mitigates mechanical issues, but also maximizes efficiency and improves driver safety. Best-in-class managed maintenance programs are a part of all successful fleet operations.

When it ain’t broke … that’s when you fix it

Prioritize preventive maintenance

More than 75% of repair shops estimate that customers who forget or ignore manufacturers’ recommended maintenance could save $100 or more per visit if they properly maintained their vehicles, so the “don’t fix it if it ain’t broke” mindset is not only dangerous, it can also be expensive. Unplanned maintenance can cost three to nine times more than scheduled maintenance, which means that postponing that $60 oil change can lead to a $6K engine problem. Preventive maintenance, or compliance to preventive maintenance schedules, saves your vehicle from wear and tear and money over time.

However, not only is money lost with repairs, but valuable time is also lost (and we all know time is money!). When you have a collision, an engine fails or another vehicle issue occurs, your driver will spend hours on the side of the road or tied up in the shop waiting on a repair. On top of that, your vehicle can be out of commission for days or weeks while waiting for a pricey fix… and if you have an important job coming up, money for an emergency rental vehicle will comes directly from your profits.

Stay up to date on the needs of your make & model

Do you know how many vehicles in your fleet can actually wait until they reach 10K miles before needing a motor oil change? Or which vehicles will need a transmission fluid change far sooner than 100K miles to avoid catastrophes? Knowing what your unique models and engine types need can be the difference between going in for scheduled preventive maintenance (PM) versus dealing with a full engine or transmission breakdown.

Having an understanding of your vehicle can also keep mechanics from upselling you on maintenance costs. Two out of three U.S. drivers distrust auto repair shops to give them a fair price. The labor rates you’re charged, along with the price of parts, should always fall in line with industry benchmarks. That takes additional knowledge, time and research. When truly understanding the intricacies of each of your fleet vehicles, you're ensuring the right maintenance decisions are being made.

Prepare for a technician shortage

How it started: Technicians today have to keep up with rapidly advancing technology — like Advanced Driver Assistance Systems, including automatic parking, lane centering and blind spot detection — that their predecessors didn’t. That’s led to a massive shortage in talent. Although programs are graduating 37,000 service technicians a year, Automotive News reports the auto industry needs 76,000 new technicians a year to keep up with new jobs and to replace retirees. That’s a net shortage of 39,000 skilled technicians annually.

But there’s a gap between this technology and the technicians’ education, as well as a gap between supply and demand of technicians entering the trade. And that gap has widened over the last few years. Technicians simply can’t learn the technology quickly enough, and there's a skilled labor shortage as it is. The high demand for auto service, combined with the extra time needed to spend on new and complicated technology, translates to rising costs.

What to look for in a technician: You may like the mom-and-pop shop down the road, but that doesn’t necessarily mean they’re up to date on how to reprogram your vehicle after the mirror is replaced and can ensure the blind spot technology is still compliant.

When turning to a maintenance management program managed by ASE-certified technicians, you know you’re working with a pre-negotiated, authorized network with the expertise to make the right call, first. Ideally, your point of contact is a former technician who still has all the practical experience, but transitioned to a desk job that's easier on the knees. (Think of them as a former NFL player turned coach.)They not only have data on hand, but they also have firsthand experience with repairs and ensure your technician is giving you a fair price. Since they have to take a test to renew certification every two years on updated technology standards, you can be .you can be confident with their knowledge.

How maintenance data can help

Maintenance data to the rescue

With so many other things to juggle, many companies with fleets don’t have the time, resources or infrastructure to track fleet data. In many cases, office managers keep (often meaningless) data in a spreadsheet they rarely make changes to; in others, data tracking simply doesn’t exist.

But if you have an expert to help start tracking data, you’d see just how valuable the numbers can be to your bottom line. Expert data capture, storage and analysis can inform benchmarking and offer a better idea of your vehicles’ life cycles. Also, you can interpret that data into actionable insights, saving money, including:

-

When to cycle out your vehicle — trained fleet experts can use maintenance data to better develop cycle strategies. For example — data experts can see that one fleet’s cargo vans regularly start incurring major repairs at 150,000 miles. Instead of racking up bills with costly and inevitable fixes, a data expert can recommend cycling out these vehicles before they reach a certain mileage.

-

How much you’re spending on a Cost Per Unit (CPU) and Cost Per Mile (CPM) Basis — tracking key metrics will help you better understand what vehicles work best for your company financially. When you have numbers to compare one vehicle's MPG and total CPM to another, you can make better business decisions about what vehicles will cut your fuel costs.

The average Joe who saved thousands with maintenance data

Maintenance data is not reserved only for fleets of 100+ vehicles. Small fleets can also save thousands when making maintenance data a priority. Here are a few examples of who maintenance data can help:

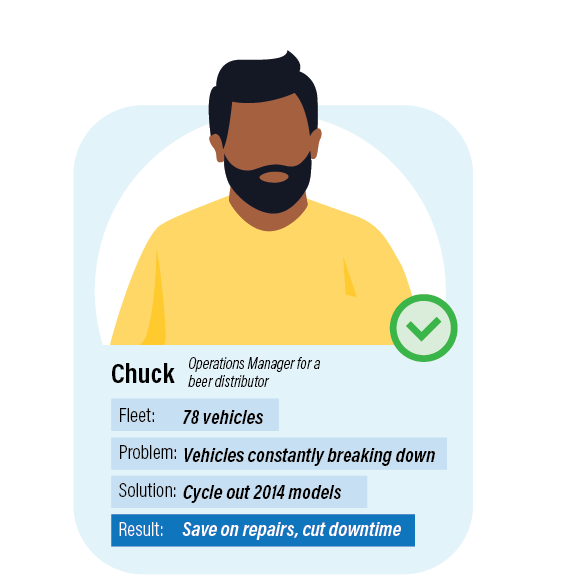

Chuck

Role: Operations Manager for a beer distributor

Fleet: 78 vehicles of multiple varieties, including Ford Transits, used by his field reps to visit clients in his 3-county territory.

The issue: His Transits are old and are constantly breaking down, losing air conditioning or having engine failures. His drivers are exasperated with the constant shop visits. His company has spent over $7,000 a month on repairs and downtime, which he assumed was inevitable.

The solution: After delaying for too long, Chuck ran a mileage analysis on all his vehicles, finding that the 2014 models were costing the most by a landslide. He opted to cycle out all his 2014 models for better-performing, newer ones. He now spends far less money each month on repairs and downtime, and his drivers are glad they can eave the shop and return to the road.

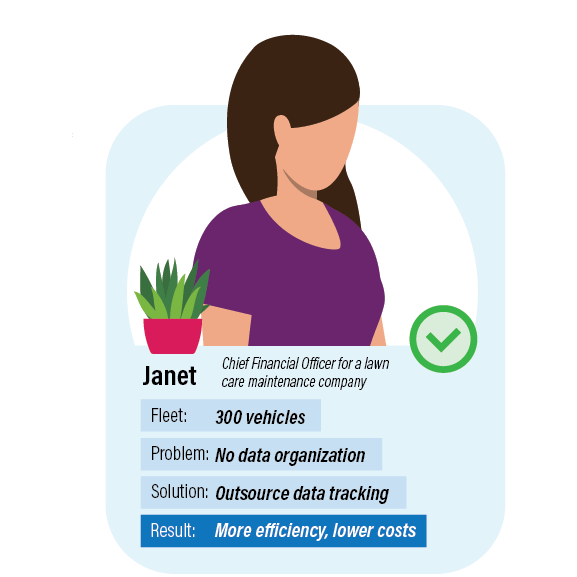

Janet

Role: Chief Financial Officer for a lawn care maintenance company

Fleet: 300 vehicles, primarily upfitted trucks and vans

The issue: While she used to track data on an Excel spreadsheet, eventually bigger issues came into play, and she let data fall by the wayside completely. For months, the fleet had no regular method for data tracking. They didn’t separate the costs of maintenance or track how much money was lost.

The solution: After paying a particularly pricey invoice, Janet decided it was time to start outsourcing maintenance data tracking (on something a little more high tech than an Excel spreadsheet). By pulling her data into an easy-to-read dashboard, they found the company was wasting thousands of dollars on repairs and maintenance. They decided to cycle out 70 underperforming vehicles for newer models. After that, their expenses decreased exponentially.

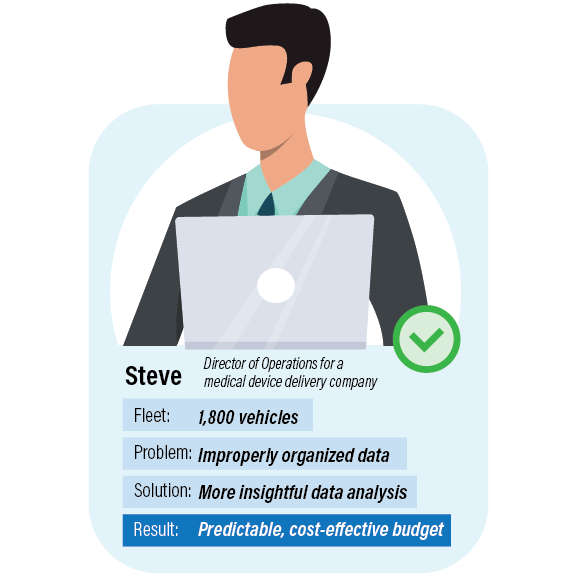

Steve

Role: Director of Operations for a medical device delivery company

Fleet: 1,800 vehicles of all varieties, upfitted specifically for equipment to send to surgery centers and hospitals

The issue: Steve outsources his fleet management to a company, but they operated on guesswork instead of hard data. With so many vehicles to manage, he was tired of spending skyrocketing amounts of money on maintenance, especially when he was paying a company to make better decisions for him. He decided to outsource to a company with a better plan for their maintenance data.

The solution: The new company pulled in data the other company didn’t, including driver downtime. The result? The amount of improper driver downtime was far too high. He was then able to rightsize the fleet. That company now operates with a highly predictable repair budgeting schedule and has saved far more this year than last year.

Pro Tips: How to save money with a managed maintenance program

Consolidate your billing

On average, it costs companies about $25 to pay an invoice. So when you consolidate your billing to only pay one invoice a month instead of hundreds of invoices each month coming from multiple vendors, you can save thousands per month in soft administration costs alone.

Turn to tech for preventive maintenance updates

Data analytics platforms can do a number of things, including:

- Monitor mechanical vehicle health

- Track when, where and how vehicles are driven

- Organize data insights into a user-friendly dashboard

Track what you save

When you outsource maintenance management, the experts should treat your money as if it is their own. That’s how you know they’re truly looking out for the best prices for your company. See how much money you can save with a free fleet consultation.